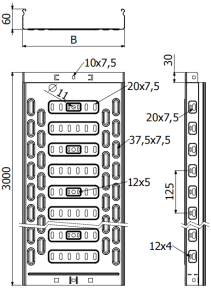

Cable tray roll forming machine cable tray production line

1 set of single cantilever decoiler

The maximum load capacity is 6 tons, the maximum material width: 1250mm

Steel coil inner diameter φ460—520, steel coil outer diameter φ1200—1600

The structure of the decoiler is: hydraulic tension, active discharge, electrical control.

The uncoiling machine body is composed of steel plate welding and machined parts.

Leveling machine

Correction rollers: upper three/lower four, one set of pinch rollers front and rear.

Leveling ring material range: maximum material width 120mm, material thickness (steel strip) 0.8-2.0mm

Structural features: It is composed of a pinch roller and a leveling roller, and the pinch roller can be adjusted individually. The feeding end of the leveling machine is equipped with a pair of guiding flat rollers and two pairs of guiding vertical rollers. The guiding vertical rollers can move in the center and at the same time.

Servo feeding, punching and cutting device

Servo structure: multi-stage feeding, multi-group memory function in memory, so that the punching accuracy is more accurate

Punching method: on-line trial production in the factory, complete all punching/cutting processes, die material: Cr12MoV.

The punch is a reformed punch with a lifting force of 250 tons to ensure that 1130 plates can pass through before and after.

The punching die is to be determined. The details must be confirmed by final confirmation of all drawings!

Feeding guide

Form: Roller type (conveying materials), with power. 4.5m X 2 knots

Function and structure: The sheet metal after guiding the punching and cutting enters the roll forming machine smoothly. The guiding device is mainly composed of an air cylinder. The guide wheel can be easily adjusted to adapt to different widths of sheets.

Main roll forming machine

Form: Double cantilever gear drive, width adjustable universal molding machine moves as a whole, can quickly and automatically (waist height and width) exchange specifications;

The rollers are forged with GCr15, and are processed by CNC after quenching. The hardness can reach HRC58-62; it has the characteristics of high strength, high hardness, high precision, and service life. Roll shaft material: 40Cr